NIQR Student Chapter, Department of EEE, Meenakshi Sundararajan Engineering College, Chennai organised a Webinar on “Secondary usage of Batteries from Electric Vehicles” on 11th Nov 2020.

Shri. Muthaiah N, Divisional Manager, Corporate Strategy and Planning, Ashok Leyland Limited, Chennai was the faculty which was attended by more than 450 students and professionals.

Dr. K. S. Babai, Secretary, Meenakshi Sundararajan Engineering College welcomed the participants and expressing her happiness with many webinars organised by NIQR for the benefit of students.

Mr. S. Rajasekaran, National President, NIQR was the Chief Guest and inaugurated the Webinar; he made the participants think deep with a question; is the EV a boon or bane for the society? and explained his viewpoints for both with lot of statistics; he touched upon the big problem of disposal of used batteries ten years from now.

- Automotive market size – Global/India

- EV market size

- Lithium Ion Batteries and its types

- Application of batteries

- Second life of batteries

- Challenges of Second life batteries

- Use cases of Second life batteries

- Recycling

The long Q&A session was well handled by the student coordinators; Dr. K. S. Babai complimented the lecture of Mr. Muthaiah and wanted NIQR and Ashok Leyland to come forward to offer more programs.

Mr. S. Manikandan, Assistant Prof-EEE, & NIQR Student Chapter Coordinator proposed the vote of thanks.

The gist of the lecture is given below.

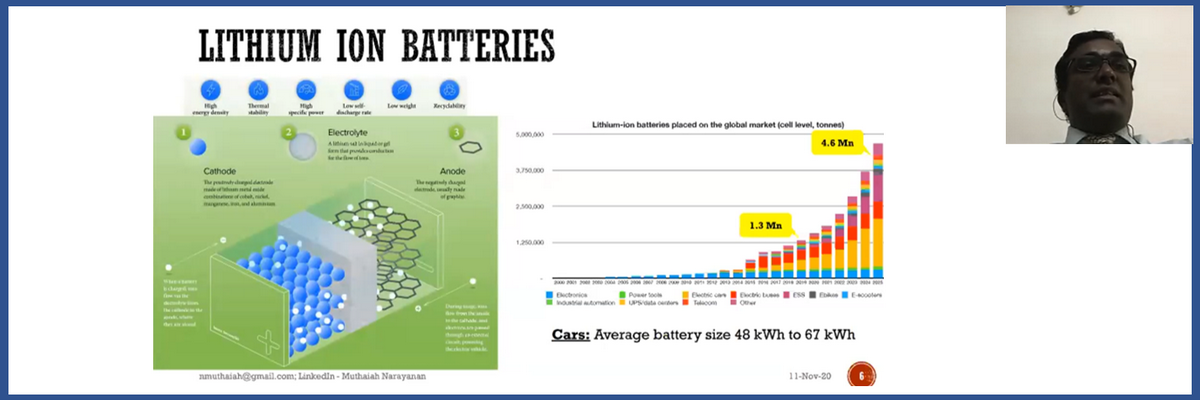

Electrification in cars have reached 2.6% of the Global car sales in the year 2019. The electrification in cars have grown massively from 8,000 units in 2010 to 2.1 Mn units in 2019. China is the largest market currently with 1 Mn units of sales and 3.3 Mn units of stock in the last year. The global EV car stock as per IEA (International Energy Agency) is expected to grow to 140 Mn units by the end of 2040 from 7.2 Mn units in 2019. With the adoption of faster electrification in other segments like Bikes, LCV’s, Buses and Trucks this is expected to grow further. Lithium Ion Batteries the key ingredient acting as the source of power for driving these vehicles have also shown a proportional growth.

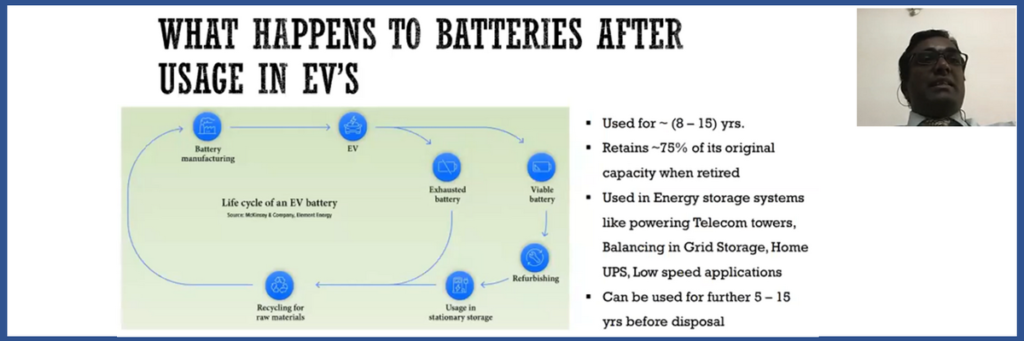

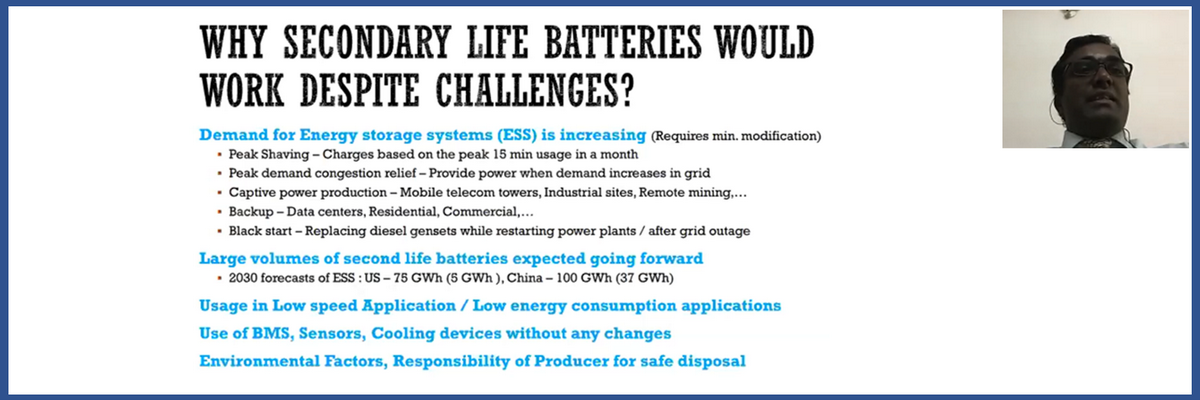

Lithium Ion Batteries are used for a period of 8-15 years in the vehicle depending on its usage, application, charging, capacity, driving conditions, temperature etc. The batteries have 70-80% of its useful storage capacity when retired from the vehicles. Such batteries can be used in secondary and tertiary applications before their final disposal (Figure 1). The secondary life batteries from Electric Vehicles can be used as Energy Storage Systems (ESS) in powering telecom towers, residential & commercial backup, peak shaving, energy arbitrage, low speed vehicle applications, UPS, grid storage etc due to their nature of demand and supply requirements. Forecasts indicate that by 2030, USA and China will have 5 out of 75 Gwh and 37 out of 100 Gwh of energy storage requirements being met by second life batteries. Usage of Lithium Ion Batteries in vehicles and energy storage systems are expected to get tripled from the current levels by the end of 2030. The secondary / tertiary batteries can be used for a further period of 5 – 15 years depending on their usage and application before their final disposal.

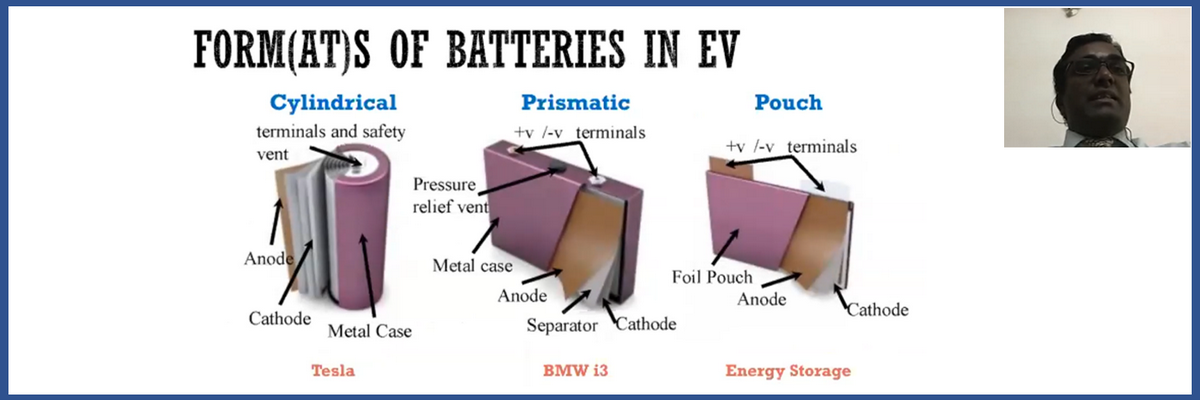

The secondary / tertiary application comes up with a lot of challenges and is complex as the secondary / tertiary user does not understand the initial information of the battery like its size, designed capacity, charging type, partial cycles, usage pattern, make, chemistry, format etc. It gets more complex because of their technological advancements in the rapidly changing environment, long storage, difficulties in collection and consolidation, refurbishing, testing and absence of standards for secondary / tertiary life. With the complexities of applications, manufacturers are also finding avenues for suitable conversions in the energy storage applications. Companies like Nissan, Daimler, Renault, China towers, Yinlong etc have commercial / pilot projects in energy storage systems currently (Energy storage, Peak shaving, off grid, Frequency regulation, telecom tower applications, batteries in low speed applications, etc). Manufacturers are also becoming more responsible and increasingly environmental conscious with the critical demand for booming precious metals in the Lithium Ion Battery. Smaller cells find a way to remanufacturing due to their expensive conversion for secondary usage. As per a recent study conducted by Mckinsey and Company in the US, it is 75% cheaper to use a battery for energy storage against grid storage to manage fluctuations in the grid. Also the grid storage by battery is having a faster response to manage the grid fluctuations.

Batteries from secondary life are expected to reach a capacity of 100 GWh by 2030. Lithium Ion Battery usage will reach 4.6 Mn tonnes (Cell level) by 2030 which currently is at 1.3 Mn tonnes for all ranges of its applications. With the increasing demand for energy storage systems across various applications, secondary life batteries can create capacities to meet the necessary demand. To reduce complexities, manufacturers have started to track the batteries from its manufacturing (cell level) till its end of life (disposal) so that the entire information required is captured and can be easily transformed into the next usage application. China and US (in certain states) have brought regulations making manufacturers responsible for the disposal of batteries after its useful life. The regulation is expected to become global shortly. India will be a major player in the EV segment by 2030 with the government adopting various measures and as part of the Electric Vehicle Initiative (EVI), governed by the IEA have accepted to electrify a minimum of 30% of the vehicle sale to EV.|